| Nanocomposites |

|

SYNTHESIS OF POLYMER/METAL NANOCOMPOSITES

Nanocomposite materials containing metal nanoparticles and polymer matrix may exhibit novel physical and chemical properties that are of high scientific and technological importance. These materials combine the physical properties of small size metal nanoparticles with those of polymeric materials in a beneficial manner. Many advanced optoelectronic and sensor devices are based on the fabrication of these materials. Because of their high surface free energy, nanoparticles tend to agglomerate. A key challenge for a potential technological use is the achievement of homogeneous dispersion of the thermodynamically unstable nanoparticles. Various methods have been applied. Generally applied methodology is detaining nanoparticles during the preparation by adding protecting agents or setting them in an inert environment. Among them, photochemical methods involving light induced reduction of metal ions such as Ag and Au complexes are of particular interest as they find a wide range of application including synthesis of metallic colloids, and metallization and patterning of films.

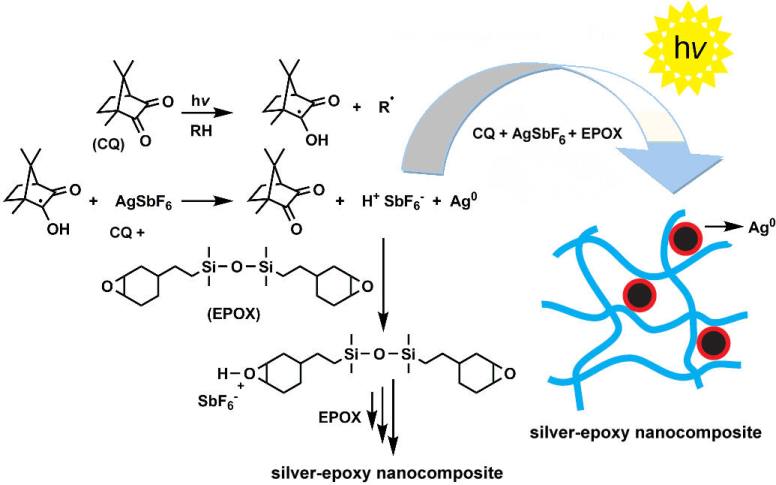

Recently, we have introduced a novel approach for the preparation of metal-polymer nanocomposites, in which nanoparticle formation and UV crosslinking process were accomplished in one pot by simply irradiating appropriate formulations, obtaining the homogeneous distribution of the nanoparticles within the polymer network without any macroscopic agglomeration. Silver or gold nanoparticles and initiaing species were formed in a single redox process.

POLYMER/CLAY NANOCOMPOSITES

The use of nanostructured fillers in the

polymer has gained significant importance in the development of

thermosetting composites. One of the more widely studied

nanocomposite strategies is the incorporation of layered

silicates into the polymer matrix. In comparison to other

nanoparticles, layered silicates belong to a unique group of

nanofillers with only one dimension on the nanometer scale. The

individual platelets of this filler are slightly below 1 nm in

thickness, and the diameter of the platelets varies between 200

and 600 nm.

Three methods have been developed over time for the synthesis of

polymer/clay nanocomposites: solution exfoliation, melt

intercalation and in situ intercalative polymerization. However,

the most common process to synthesize polyether/clay layered

silicate nanocomposites is via the in-situ polymerization, the

monomer, together with the initiator and/or catalyst, is

intercalated within the silicate layers and the polymerization

is initiated either thermally or chemically in situ. The chain

growth in the clay galleries triggers the clay exfoliation and

hence the nanocomposite formation.

We have described several synthetic approaches, namely cationic ring opening polymerization, activated monomer polymerization, photoinitiated free radical polymerization and “click chemistry” allowing the preparation of polymer/clay nanocomposites.