| Conjugated Polymers |

|

T

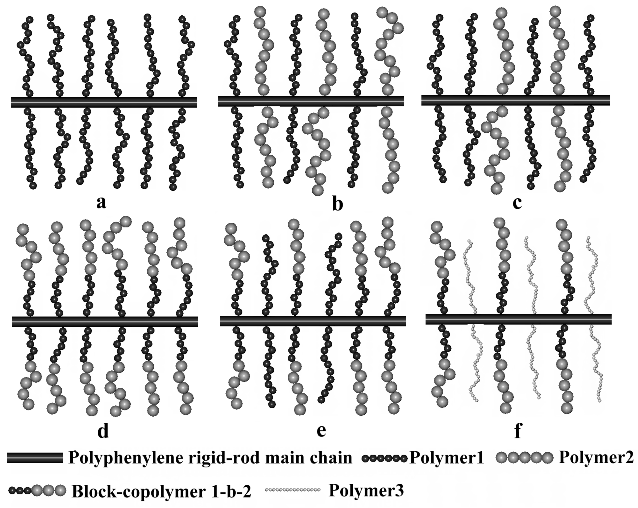

here is a long interest to prepare soluble conjugated polymers so that polymerization, purification, characterization and processability to be carried out in solution, polymers to be free defects, with a known structure and to form thin films. Owing to their intrinsic chemical structure, conjugated polymers are insoluble in most organic solvents and improving their solubility and processability has been became an important objective that focused many research efforts. From the chemistry viewpoint this disadavantage could be surpassed by design of adequate monomers and introduction of solubilizing side chains onto the conjugated backbone is a very used and efficient method for solubility improving. However, the side substituents used until now are short alkyl chains or other functional substituents for introduction of other supplementary properties; liquid crystallinity, optical activity, ionic groups, etc.The attaching of usual polymer short chains with a well defined length; i.e., polystyrene, polytetrahydrofuran, polylactone and poly-N-acetyl ethylenimine chains, onto polyphenylenenes and polythiophenes and properties of branched copolymers have reported.

Poly(p-phenylene) (PPP) is a typical conjugated,

electroluminescent polymer for light emitting devices in

combination with excellent mechanical properties and thermal and

thermo oxidative stability. The key structural factor in

describing the supramolecular ordering of PPP is their

anisotropic shape, which follows from a rodlike architecture

that differentiates them from flexible polymers. Unfortunately,

PPPs are insoluble in many organic solvents, which limit their

processability. Therefore, attachment of conformationally mobile

alkyl side chains to the backbone has been important because it

has allowed the controlled synthesis of soluble and processable

PPPs with high molecular weight. In view of the expected large

persistence length of the main chain and of the flexibility of

the side chains, such molecules have been termed “hairy-rod”

polymers. On combining a stiff, insoluble, rod-like polymer such

as PPP with a soft coil, for example polystyrene, it is possible

to form a new polymer with novel and interesting properties.

The design process, the essence of which is the chemical control

of size and shape of PPPs, ultimately leads to conjugated

polymers of varying, controlled dimensionality.

Our studies focused on the synthesis of PPP type graft

copolymers that can present nanostructures between a conductive

and an insulating polymer, by using the macromonomer technique

via controlled polymerizations [ATRP or ROP (Ring Opening

Polymerization)] as versatile “tools”, combined with

metal-catalyzed Suzuki or Yamamoto polycondensation , specific

to the obtainment of soluble, high molecular weight, conjugated

polymers.