HIGH PERFORMANCE WINDOW SYSTEMS

Windows are possibly the most complex and interesting elements in building design which have dominant feature of a building’s appearance. They provide light and fresh air, and offer views that connect the interior spaces with the outdoors. However, windows have also represented a major source of heat loss in winter as well as unwanted heat gain in summer. It is now possible to have expansive views and daylight without sacrificing comfort and energy efficiency. Today’s high performance window systems provide energy efficiency while increasing occupant comfort by offering new alternatives for the design of windows as a result of the advances in window technology. The benefits of high performance windows are summarized as follows:

Cooling and heating season energy savings

Improved daylight and view

Improved comfort

Reduced condensation

Reduced fading by reducing UV radiation

Lower costs for mechanical equipment

Here, the basic requirements which have to be considered in window design and the components of a high performance window assembly are explained.

1. Basic Issues in Window Selection and Design

Typically, aesthetics and costs are major factors in making design decisions about windows. The need to reduce unwanted heat loss and heat gain has been the major energy related issue in window design. In addition, window design is influenced by various functional requirements like air and water tightness, as well as structural and acoustical performance.

1.1.1. Basic Properties of Glass

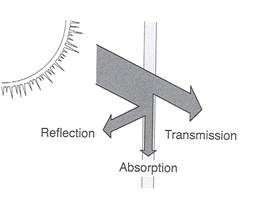

The four basic properties of glazing that affect radiant energy transfer are transmittance, reflectance, absorptance and emittance (Figure 1).

Figure 1 Solar radiation through a glazing material is either reflected, transmitted or absorbed

Transmittance: Transmittance, refer to the percentage of radiation that can pass through glazing. Transmittance can be defined for different types of light or energy, e.g., visible transmittance, UV transmittance and total solar energy transmittance which of each describes a different characteristic of glass.

Reflectance: The natural reflectivity of glass is dependent on the type of glazing material, the quality of the glass surface, the presence of coatings and the angle of incidence of the light.

Absorptance: Energy that is not transmitted through the glass or reflected off its surfaces is absorbed. Once glass has absorbed any radiant energy, the energy is transformed into heat, raising the glass temperature.

Emittance: when solar energy is absorbed by glass, it is either convected away by moving air or reradiated by the glass surface. This ability of a material to radiate energy is called its emissivity.

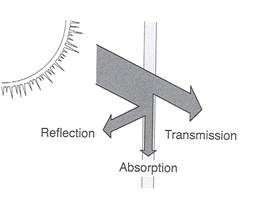

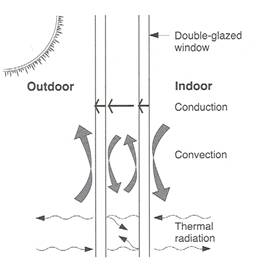

When a window separates a cold outdoors from a warm interior heat transfer will occur via conduction through glass and frame materials, convection/conduction through air spaces, and long-wave radiation between glass surfaces on either side of an air gap.

1.1.2. Energy Related Properties of Windows:

Increasing requirements for energy conservation have resulted in greater consideration of the effect windows have on the overall heat loss from an external wall. A large area of glass, depending on its orientation, can also result in excessive solar heat gain which causes discomfort. Thermal transmittance (U-value), solar heat gain coefficient (SHGC) and visible transmittance (VT) are the properties of the window systems, which can be used as the basis for quantifying energy performance and allow accurate comparison at window system level.

When there is a temperature difference between inside and outside, heat is lost or gained through the window frame and glazing by the combined effects of conduction, convection and long-wave radiation (Figure 2). The U-value of a window system represents its overall heat transfer rate or insulating value. The U-value of the total window system combines the insulating value of the glazing system, edge effects in the glazing system and window frame and sash. The U-value of the glazing system is affected primarily by the total number of glazing layers, their dimension, type of gas within the cavity of the glazing system, thickness of the cavity, type of spacer in between the glass panels and the characteristic of coatings on the various glazing surfaces. The U-value of the window glazing have been decreased throughout the years e.g. from 3.0 W/m2K to 1.6 W/ m2K and further down to 1.2 W/ m2K for double glazing.

Figure 2 Components of heat transfer through a window that are related to U-value

1.1.2.2. Solar Heat Gain Coefficient (SHGC)

Regardless of outside temperature, heat can be gained through windows by direct or indirect solar radiation. The ability to control this heat gain through windows is measured in terms of the solar heat gain coefficient. The SHGC generally refers to total window system performance and is an accurate indication of solar gain under wider range of conditions. The solar heat gain coefficient is expressed as a dimensionless number from 0 to 1.

1.1.2.3. Visible Transmittance (VT)

Visible transmittance is an optical property that indicates the amount of visible light in the visible portion of the spectrum that passes through the glass. It affects energy by providing daylight that creates the opportunity to reduce electric lighting and its associated cooling loads. Transmittance is influenced by the glazing type, the number of layers and any coatings that might be applied to the glazings. The higher the VT, the more light is transmitted to the interior. Visible transmittance is an important factor in providing daylight, views, and privacy as well as in controlling glare and fading of interior furnishings.

1.1.2.4. Air Leakage (Infiltration)

Air leakage (infiltration) can be defined as ventilation that is not controlled and usually not wanted. Heat loss and gain also occur by air leakage through cracks around sashes and frames of the window system. This effect is often quantified in terms of the amount of air passing through a unit area of window under given pressure conditions. Tight sealing and weather-stripping of windows, sash and frames is of paramount importance in controlling air leakage.

High performance window systems fulfill a number of requirements for the well-being of the occupants, occupant productivity and contributing to health. High performance window directly affect several interior design attributes such as daylight, glare, view and thermal comfort. Whether windows are operable and occupants can individually control light, heat and air flow also contribute to both psychological and physical well-being.

The amount of daylight entering a window depends on a number of external factors including the direction of the window faces, external obstructions such as trees or surrounding buildings and presence of shading devices such as overhangs, awnings. Windows are expected to permit daylight to enter a space. The design of a window and choice of glazing can dramatically affect the quantity of daylight in a space and how it is experienced. Daylight illuminance not only varies depending on location within a space; it also varies with the time of day and season of the year.

Daylight design is far more sophisticated than simply providing a window with a high enough visible transmittance. More daylight does not necessarily equate to better lighting conditions. It is a matter of balancing daylight admission with glare control as well as providing uniform light distribution. The usability of daylight is dependent on the task in the space.

Although daylight is generally desirable, too much direct light, especially through smaller openings can result in uncomfortable glare. Glare problems result when the light source is much brighter than the surrounding room surfaces and too intense for the naked eye to handle. If a window that reduces visible transmittance is chosen, then the potential for glare will be reduced as well. The goal is to provide as much daylight as possible while controlling glare problems. Glare depends on orientation, the presence of shading devices, and other window properties and design conditions.

View is the most subjective of the attributes in window performance. Window size, shape, proportion and view content greatly influence human perceptions such as spaciousness as well as the attractiveness and acceptability of the window itself – shape and content are left to designer. The view seen from a window is affected by window area, the visible transmittance of the glass, the fraction of window area not obstructed by permanent exterior shading devices (overhangs and fins), and the percentage time that interior shades do not obstruct the view.

Thermal comfort is determined by air temperature, relative humidity, air movement, mean radiant temperature, the presence of direct solar radiation and occupants’ clothing and activity levels. Windows affect human comfort in several ways. During cold periods exterior temperatures drive interior glass surface temperatures down below the room air temperature and the glass surface temperature depends on the window’s insulating quality. If people are closer to a cold surface window, they can experience significant heat loss and feel uncomfortable.

Drafts near windows are the second major source of winter discomfort. Cold temperature induced drafts occur at the same time as radiant discomfort. Drafts can also be caused by windows with significant air leakage resulting poor installation and/or ineffective weather-stripping.

Direct sun has impacts on thermal comfort as well especially during warm periods. The glazing surface temperature increase due to solar radiation depends on the absorptance of the glass and environmental conditions.

Operable windows can contribute to improved thermal comfort. People have the opportunity to regulate their own thermal environment and use air movement from natural ventilation to feel cooler at higher temperatures. Even though operable windows may not save significant amounts of energy, the fresh air and sense of control they provide contributes to occupant satisfaction.

In addition to energy and human factor concerns, windows are influenced by other requirements that at times limit the ability to achieve energy efficiencies within acceptable cost parameters. These technical issues include acoustical performance, structural design, water and weather tightness, condensation resistance, durability, fire protection and blast resistance.

Windows that are susceptible to water penetration and air leakage are also susceptible to flanking. Therefore improving the structural and energy performance of a window system will also improve its acoustic performance. The most significant step which can be taken to reduce sound transmission is to minimize air infiltration. Using tight fitting products will make a significant difference over moderate or poorly sealed products. Care should be taken to ensure that the windows are properly installed to minimize infiltration between the wall and the window frame. The steps that can be taken to reduce direct sound transmission are:

using wide air / gas gaps between glass panes

replacing air with argon, krypton or SF6 between the glass panes

using different thickness of glass layers in a glazing system

Acoustically efficient windows often have multiple rows of gaskets at operating joints.

Structural loads imposed on window system are met by a variety means including glass and frame materials as well as connections. Minimizing glass, framing and sash deflection under structural loading is important to the proper selection of glass and framing components. Excessive deflections can lead to glass and frame cross-section breakage as well as air and water infiltration. Allowable deflections depend on the building construction type and the type of glass used. Larger and/or more frequent framing cross sections are required to minimize deflections.

In addition to frame materials and connections, the type of glass affects structural performance of the window system. The strength of annealed glass can be enhanced to meet higher mechanical and thermal loads by subjecting it to a heat treatment process. This process locks a residual stress distribution in the glass and subsequently increases its overall strength. Depending on the surface compression left in the glass from the heat-strengthened process the glass is either referred as heat strengthened or fully tempered.

In addition, the increase in the thickness of glass enhances its ability to resist a given load. Glass thickness typically has its most significant impact on solar gain. A thicker glass of the same type has a reduced solar transmittance while thicker glass has an insignificant impact on heat loss rates.

1.3.3. Water Control and Weatherproofing

Preventing water transmission and minimizing unwanted air movement are prime requirements of window systems. Air infiltration and exfiltration through window system is the uncontrolled movement of air through joints in the product and in the surrounding framing. Infiltration is the movement of air from outside in, while exfiltration is the movement of air from the inside out. Infiltration and exfiltration occurs due to poor product design, poor quality control during product manufacturing and poor construction detailing and /or installation.

Wind-driven rain impacts different points on a building envelope at different angles, speeds and volumes. Water that appears to be the result of leaking windows is often a result of penetration at another location. The most obvious source is the perimeter sealant between the window product and the exterior wall system. The features to minimize water penetration of the window systems are summarized below:

Operating window products can be designed to acknowledge that some water will penetrate the exterior plan of the product. The water collected at the sill, must be allowed to exit through weep holes. A window which does not weep to the exterior will leak to the interior.

Internal drain path directs water from internal sealant joints in order to keep sealants from failing and divert water from the edge seals of insulating glazing units.

Sub-sills and flashing provide water protection for the space between the window product and the opening in the wall. Sub-sills are tracks secured to the bottom of the rough opening in a building to aid in window installation and to provide some redundancy in preventing water from entering building cavities. Flashing are generally fabricated from sheet metal to fit around the corners of the lower portion of the rough opening.

Gaskets and sealants failure will adversely affect window performance, including lowering resistance to water and air infiltration and reductions in thermal efficiency. Gaskets and sealants which are applied in the field must remain resilient over the expected life of the window.

1.3.4. Condensation Resistance

Condensation is a problem obviously associated with windows, caused by the interaction of a number of factors – ventilation rate, temperature and the form of construction. Poorly or moderately insulated windows can cause to the formation of condensation in interior spaces. Besides, when water enters the framing of the window system, it creates a short circuit that can compromise the insulation value of the sash and framing members and increase heat transfer through the product, reducing the window’s energy efficiency. Condensation can cause the degradation of materials such as insulation and thermal barriers, decreasing their thermal efficiency.

In addressing condensation resistance, designers attempt to keep all surface temperatures above the dew point, taking into account indoor and outdoor temperatures, relative humidity, air movement and specific elements of the buildings that affect air movement around window (e.g., use of heavy drapes). The high inside surface temperatures associated with a low U-value will reduce the potential for condensation where air movement is maintained and potential for stratification is minimized.

A durable window system does not deteriorate rapidly and lasts a long time. Important components of a window product’s durability include the ability to resist condensation and air and water infiltration while maintaining thermal and structural performance as well as aesthetic features.

A durable window system must address climate, including exposure to extreme weather, as well as particular site microclimate conditions. Regular maintenance is important to maintain product durability; degradation of structural and material components will negatively affect durability and energy performance.

Key fenestration components affecting durability that should be carefully considered during design include; framing components, glazing units, gasket and sealant materials, gas infill materials and hardware and mechanical devices used to operate system elements. The sensitivity of the products to heat, ultraviolet radiation and moisture should be taken into account.

A window is defined as consisting of:

Window glazing

Glass (single, double, triple etc.)

Spacer

Cavity gas

Glass coating (low-e, solar control coatings, etc.)

Window frame

Various frame/casing structures

Structural frame materials

Highly thermal insulating materials

The window systems can be formed from a wide range of glazing systems (glass types, gas materials and spacer materials), frame systems which have great impacts on total window performance. In addition to the glazing and frame materials, the window is often integrated with various attachments and components that provide sun control and daylight redirection.

Figure 3 Window system components

The glazing is usually the larger part of a window. One of the shortcomings of glass is relatively poor insulating qualities. Multiple panes of glass with air spaces in between improve the insulating value considerably. Therefore in the context of high performance window systems, transparent component should be considered as a system with several glass types with different types of coatings, gas materials between the glass layers and spacers made of different materials as an insulated glazing unit (IGU). Insulated glazing units are hermetically sealed, multi-pane assemblies consisting of two or more glazing layers held and bonded at their perimeter by a spacer bar typically containing a desiccant material. The desiccated spacer is surrounded by a sealant on at least two sides that adheres the glass to the spacer.

Figure 4 Insulating Glazing Unit (IGU) Construction Detail

Traditionally windows have been made of clear glass. With float technology extremely flat glass surfaces with uniform thickness and panes without visual distortions have been produced. Most common types of glass used in a glazing system are clear, tinted, low emissivity (low-e) coated and reflective coated glass.

Relative to all other glazing options, clear single glazing allows the highest transfer of energy while permitting the highest daylight transmission.

The tints absorb a portion of light and solar heat. Tinting changes the color of the window and can increase visual privacy. The primary uses for tinting are to reduce glare from the bright outdoors and reduce the amount of solar energy transmitted through the glass.

Tinted glazings retain their transparency from the inside, although the brightness of the outward view is reduced and the color is changed. The most common colors are neutral gray, bronze and blue green which do not greatly alter the perceived color of the view and tend to blend well with other architectural colors. Many other specialty colors are available for particular aesthetic purposes. Tinted glazings are specially formulated to maximize their absorption across some or all of the solar spectrum and are often referred to as “heat absorbing”. All of the absorbed solar energy is initially transformed into heat within the glass, thus raising the glass temperature. Heat absorbing glass provides more effective sun control when used as the outer layer of a double-pane window.

There are two categories of tinted glazing: the traditional tints that diminish light as well as heat gain and spectrally selective tints that reduce heat gain but allow more light to be transmitted to the interior. The traditional tinted glazing often forces a trade-off between visible light and solar gain. For those bronze and gray tints, there is a greater reduction in visible transmittance than there is in solar heat gain coefficient. This can reduce glare by reducing the apparent brightness of the glass surface, but it also reduces the amount of daylight entering the room. For windows where daylighting is desirable, it may be more satisfactory to use a high-performance tint or coating along with other means of controlling solar gains. Tinted glazings can provide a measure of visual privacy during the day when they reduce visibility from the outdoors. However, at night the effect is reversed and it is more difficult to see outdoors from inside. Tinted glazing is much more common in commercial windows than in residential windows. Residential solar gains are more typically controlled using blinds, drapes or other decorative window treatments.

If larger reductions are desired in solar gains, a reflective coating can be used to lower the solar heat gain coefficient by increasing the surface reflectivity of the material. These coatings usually consist of thin metallic layers. The reflective coatings come in various metallic colors (silver, gold, bronze) and they can be applied to clear or tinted glazing. As with tinted glazing, the visible transmittances of reflective glazings are usually reduced substantially more than the solar heat gain coefficient. Reflective glazings are usually used in commercial buildings for large windows, for hot climates or for windows where substantial solar heat gains and/or glare are present.

There are two types of Low-E coating. High-solar-gain Low-E coatings primarily reduce heat conduction through the glazing system. These Low-E glass products are often referred to as pyrolitic or hard coat Low-E glass, due to the glass coating process. The properties presented here are typical of a Low-E glass product designed to reduce heat loss but admit solar gain. High solar gain Low-E glass products are best suited for buildings located in heating-dominated climates.

Low-solar-gain Low-E coatings (spectrally selective), for hot climates reduce solar gain by blocking admission of the infrared portion of the spectrum. These Low-E products are often referred to as sputtered (or soft-coat) due to the glass coating process. This type of Low-E product, sometimes called spectrally selective Low-E glass, reduces heat loss in winter but also reduces heat gain in summer. Compared to most tinted and reflective glazings, this Low-E glass provides a higher level of visible light transmission for a given amount of solar heat reduction. Low solar gain Low-E glazings are ideal for buildings located in cooling-dominated climates.

Smart window is a special type of glass which when activated can turn from a clear to transparent state to dark, semi-transparent or opaque state, and vice-versa. It is used to control solar radiation entering the building, preventing overheating and glare.

Photochromics: Photochromic materials change their transparency in response to light intensity. Photochromic materials have been used in eye glasses that change from clear in the dim indoor light to dark in the bright outdoors.

Thermochromics: Thermochromics respond to temperature. Such windows could turn off the sunlight when cooling loads become too high. The temperature of the glass is a function of solar intensity and outdoor and indoor temperature.

Liquid Crystals: Liquid crystal windows switch quickly from a transparent state to a diffuse white state. The primary function is to provide privacy and control glare as a substitute for conventional shading devices. In the diffuse state liquid crystals are primarily forward scattering so there is little control over solar heat gain.

Electrochromics: The most promising switchable technology today is electrochromic (EC) windows. An electrochromic coating is typically five layers, about one micron thick and is deposited on a glass substrate. When a voltage is applied between the transparent electrical conductors, a distributed electrical field is set up. The effect is that the glazing switches between clear and transparent blue-tinted state with no degradation in view.

An improvement that can be made to the thermal performance of insulating glazing units is to reduce the conductance of the air space between the layers. The hermetically sealed space between glass panes in an IGU is most often filled with air. In some cases argon and krypton gas are used instead to further reduce the energy transfer. Manufacturers have introduced the use of argon and krypton gas fills, with measurable improvement in thermal performance. Argon is inexpensive, nontoxic, non-reactive, clear, and odorless. The optimal spacing for an argon-filled unit is the same as for air, about 12 mm. Krypton has better thermal performance, but is more expensive to produce. Krypton is particularly useful when the space between glazings must be thinner than normally desired, for example, 6 mm. The optimum gap width for krypton is 9 mm. A mixture of krypton and argon gases is also used as a compromise between thermal performance and cost.

The spacer separates the panes of glass and provides the surface for primary and secondary sealant adhesion. In addition, the spacer system must serve a number of functions as:

accommodating stress induced by thermal expansion and pressure differences;

providing a moisture barrier that prevents passage of water or water vapor;

providing gas-tight seal that prevents the loss of gas in the air space;

creating an insulating barrier that reduces the formation of interior condensation at the edge.

Several types of spacers are used in glazing system construction today. Each type provides different heat transfer properties, depending on the spacer material and geometry. In IGU construction warm-edge spacers reduce edge heat transfer by substituting materials such as stainless steel, galvanized steel, tin plated steel, polymers or foamed silicone that have lower thermal conductivity than aluminum.

Figure 5 Aluminum spacer

Window frame is an important part of a window system. Looking at a window with a total area of 1.2 x 1.2 m2 and window frame with a with of 10 cm, the area occupied by the frame is 30% of the total and depending on the frame material the frame has a U-value higher than the glazing U value.

Window frames can contain many different materials, typically solids or small enclosed air spaces, with significantly different thermal conductivities.

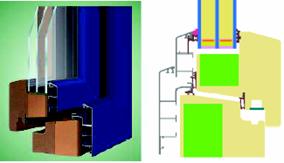

Aluminum window frames are light, strong, durable, and easily extruded into the complex shapes required for window parts. Aluminum can be fabricated to extremely close tolerances to create special forms for the insertion of glazing, weather-stripping and thermal breaks. Aluminum frames are available in anodized and factory-baked enamel finishes that are extremely durable and low-maintenance. The biggest disadvantage of aluminum as a window frame material is its high thermal conductance. It readily conducts heat, greatly raising the overall U-factor of a window unit. In cold climates, a simple aluminum frame can easily become cold enough to condense moisture or frost on the inside surfaces of window frames.

The most common solution to the heat conduction problem of aluminum frames is to provide a "thermal break" by splitting the frame components into interior and exterior pieces and use a less conductive material to join them. Current technology with standard thermal breaks has decreased aluminum frame U-factors (heat loss rate) from roughly 6 W/m2K to about 2.5 W/m2K. However it is a problem to include thermal breaks in the thinner sash components that hold the glazing. In hot climates, where solar gain is often more important than conductive heat transfer, improving the insulating value of the frame can be much less important than using a higher-performance glazing system.

Figure 6 Thermally broken aluminum frame section

The traditional window frame material is wood, because of its availability and ease of milling into the complex shapes required to make windows. Wood is favored in many residential applications because of its appearance and traditional place in house design. Wood windows are manufactured in all configurations from sliders to swinging windows. From a thermal point of view, wood-framed windows perform well with frame U-values in the range of 1.2 W/m2K to 1.6 W/m2K. The thicker the wood frame the more insulation it provides. Wood is not intrinsically the most durable window frame material, because of its susceptibility to rot, but well-built and well-maintained wood windows can have a very long life. Water repellent and/or chemical treatments can be applied in the factory to reduce swelling and warping, improve paint retention and increase wood’s resistance to decay and insect attack. Paint protects the exterior surface and allows an easy change in color schemes.

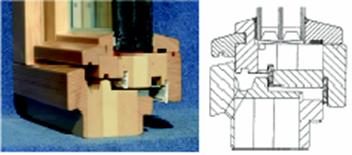

Figure 7 Wood frame sections

Vinyl, also known as polyvinyl chloride (PVC), is a very versatile plastic with good insulating value. Vinyl window frames do not require painting and have good moisture resistance. Because the color goes all the way through, there is no finish coat that can be damaged or deteriorate over time. Some vinyl window manufacturers are now offering surface treatments like laminates (wood veneer, paintable/stainable, maintenance free) and coatings. These products increase color selection and surface appearance options. Recent advances have improved dimensional stability and resistance to degradation from sunlight and temperature extremes.

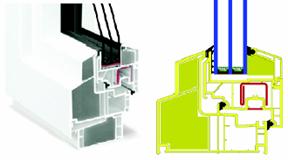

In terms of thermal performance, vinyl frames are comparable with wood, while there are minor differences, depending on the frame construction. Small hollow chambers within the frame reduce convection exchange, as does adding an insulating material.

Figure 8 Vinyl frame sections

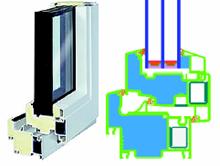

Manufacturers are increasingly turning to hybrid frame designs that use two or more frame materials to produce a complete window system. The wood industry has long built vinyl- and aluminum-clad windows to reduce exterior maintenance needs. Vinyl manufacturers and others offer interior wood veneers to produce the finish and appearance that many homeowners desire. Split-sash designs may have an interior wood element bonded to an exterior fiberglass element. We are likely to see an ever-increasing selection of such hybrid designs as manufacturers continue to try to provide better-performing products at lower cost. It may be important for a homeowner to learn about these materials from the perspective of maintenance requirements and options for interior finishes. However, it becomes increasingly difficult to estimate the thermal properties of such a frame from simple inspection.

Figure 9 Hybrid frame sections

3. The Complete Window Assembly

Although glazing materials have traditionally been the focus of much of the innovation and improvement in windows, the overall performance of any unit is determined by the complete window assembly. The assembly includes the operating and fixed parts of the window sash and frame, weather-strips, sealants, gaskets for weatherproofing as well as associated hardware, ironmongery and accessories.

Figure 10 Window Assembly

3.1. Window Casement Operation

Common alternative ways of providing opening lights or casements is given Table 1 by considering their properties regarding protection against weather, sealing and fittings.

Table 1 Comparison of types of movement for windows

|

Types of movement for windows

|

Drawing

|

Protection against weather with minimal opening |

Notes regarding sealing |

Notes regarding fittings |

|

Side hung window opening inwards

|

|

No |

Also strikes seals outwards (during wind and rain) |

Cantilevering sash generates moment |

|

Vertical pivot window

|

|

No |

Horizontal seals offset |

Load carried centrally |

|

Hopper window

|

|

Yes |

Only limited rebate possible at bottom |

Secure sash against falling |

|

Top-hung window

|

|

Yes |

Employed in regions with high winds |

Sash must be locked in open position |

|

Horizontal pivot window |

|

Yes |

Vertical seals offset |

Sash sags when open |

|

Horizontal sliding window

|

|

No |

Bottom rebate possible, contact pressure needs extra feature |

Tall narrow formats can jam |

|

Vertical sliding window

|

|

Top:yes Bottom:limited |

Bottom rebate possible, contact pressure needs extra feature |

Compensation for self-weight can jam |

|

Push-out window |

|

Limited (with additional element over top opening) |

No weather protection even at minimum opening |

Scissors mechanism must transfer wind forces |

3.2. Fixing and Connection Components in the Window Assembly

Being an opening in the wall a window needs special consideration and requires the combination of different materials for preventing rain and wind penetration. Three main connection joints in a window system are:

window sash – wall junction,

casement – sash junction

glazing unit – sash junction.

The components used in the sash – wall junction

Sub-frames and metal anchorages (stainless steel) are used for fixing the frame system to wall system

Compression seals (gaskets, mastics, etc.) are inserted at the perimeter of the joint for water control, weather proofing

Window sills are sloped sill to throw of the water for water control

Foamed silicone or polyurethane foam are used for filling the gaps to avoid cold bridges

The components used in the casement – window sash junction

Hinges, bolts and locking systems are used for fixing and providing casement movement

Weather-stripping (EPDM, neoprene) are for weather proofing

Weather-stripping is an essential component of the operable part of a window. It must be able to flex each time the window is opened and return to its original shape each time the window is closed. Compression weather-stripping squeezes and expands with window operation. Materials used for compressible weather-stripping include felts, springy metal or plastic strips and synthetic rubber gaskets.

Glazing unit – window casement junction

Gaskets (epdm), glazing tape are used for weather proofing

No matter how advanced the glazing and frame materials may be in a window system, the ultimate performance depends on the quality of its installation. Improper installation can cause air leakage, unnecessary heat loss, condensation and water leakage. This is not only may lead to diminished energy performance but deterioration of walls, insulation and the window system itself. Essentially, installing a window creates a break in several aspects of the building envelope. A properly installed window must maintain barriers keeping air and water from penetrating the wall and it must restrict vapor flow. It must also reduce heat loss and condensation around the window unit.

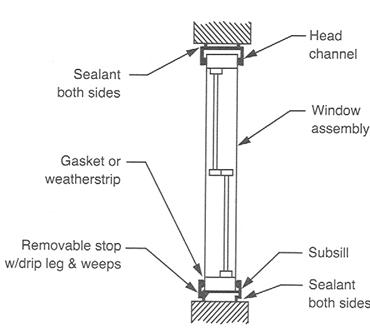

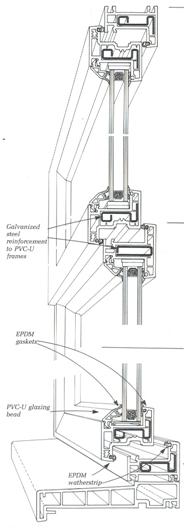

There are important differences in the details of how a window is installed depending on the type of construction or exterior cladding material. In addition each operator type, frame material have its own installation techniques. In Figure 11, a side hung wood framed window assembly example is presented.

Figure 11 Side hung wood and PVC framed window assemblies

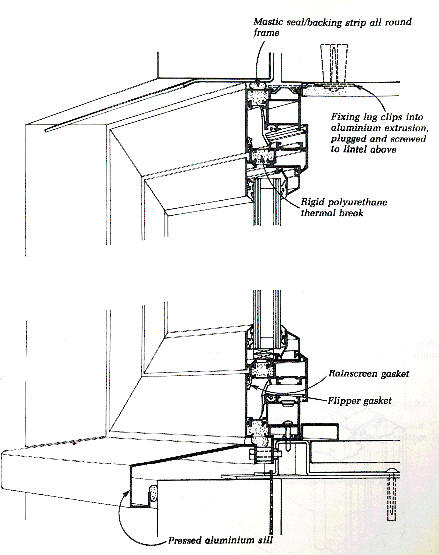

In Figure 12, a thermally broken aluminum frame window assembly which is installed with a metal sub-frame is presented. This type of window is useful where draught-free ventilation at low level is desirable. The window assembly is double weather-stripped with an external rainscreen gasket and a central flipper gasket. The aluminum sections have a thermal break of rigid polyurethane. Both frame and sill are fixed by lugs that are plugged and screwed to the inner leaf of masonry.

Figure 12 Aluminum bottom hung window

Shading devices can be used to reduce glare and heat gain during the day and heat loss at night, provided they are appropriate to location and orientation.

Exterior shading is more effective in reducing heat gains because it intercepts and sheds solar beams before they strike the glass.

Fixed horizontal overhangs: Fixed horizontal overhangs exclude high-angle sunlight but reduce daylight penetration and are appropriate for south orientation. Thus, they are most appropriate where light levels are high and overheating is a problem. Continuous overhangs provide much more shade than those which extend across the width of the window only.

Fixed vertical fins: Low angle direct sunlight is more difficult to screen. Vertical elements perform better on east and west facades. Fixed vertical fins if they are to be really effective and exclude a great deal of daylight and obstruct view.

![]()

![]()

a. fixed horizontal (overhang) b. fixed vertical (fins) c. fixed vertical and horizontal

Figure 13 Fixed exterior shading devices

Interior shading devices tent to be cheaper and more easily adjustable. They protect a room’s occupants against the immediate effects of sunlight and against glare, but are not so effective at reducing heat gains because sunlight heats up the shades and the air around them. Most window system has some type of internal shading to provide privacy and aesthetic effects as well as to give varying degrees of sunshine control. Blinds, drapes and awnings can allow the user to more readily tune light levels at any time.

Interior shade options vary from the traditional roller shades, venetian blinds, drapery and blackout screens to blinds located between the panes of an insulated glazing unit. The shade material and location of the shade in the window wall dictates the degree of daylight transmission and solar heat gain rejection. Between-pane shades perform somewhere between exterior and interior shades depending on the size of the glazing cavity and whether it is ventilated. For roller shades daylight, solar heat gain transmission, view, and privacy can be controlled by the perforation of the shade, shade weave, changes in material over the height of the shade. The venetian blind has second option for movement – tilt angle – that enables it to control daylight and allow partial view while fully blocking direct sun.

Roller shade venetian blind

Figure 14 Interior shading devices

4.3. Motorized Shading Systems

There has been increasing interest in motorized shading systems due to recent trend toward all-glass, fully-transparent facades. Automated shading systems have significant potential to reduce energy use and improve environmental quality. Motorized shades typically rely on tubular motors mounted in the roller tube or head rail of the shade.

Individually addressed and controlled shades enable the building owner to attain complete flexibility in layout, reconfiguration and operations over the life of the building with out rewiring because the control grouping can be reconfigured in software. If automated, the zoning needs to be properly planned to ensure the best match between energy management needs, individual personal comfort and functional task.

A Green Vitrivius, Principles, and Practice of Sustainable Architectural Design, European Commission, Directorate General XVII for Energy and Architect’s Council of Europa, James and James Science Publishers, 1999.

John Carmody, et.all., Window Systems for High Performance Buildings, W.W. Norton Company, New York, 2004.

John Carmody, et.all., Residential Windows – A Guide to New Technologies and Energy Performance, W.W. Norton Company, New York, 2000.

Dariush Arasteh, Advances in Window Technology, Lawrence Berkeley National Laboratory Report No:LBL-36891, 1995.

Eleanor Lee, et.all., High Performance Commercial Building Facades, Lawrence Berkeley National Laboratory Report No:LBNL-50502, 2002.

ASHRAE Fundamentals, Atlanta, Ga., American Society of Heating, Refrigerating, and Air-Conditioning Engineers, 2005.

Thomas Herzog, et.all., Façade Construction Manuel, Birkhauser – Publishers for Architecture, Munich, 2004.

Michael McEvoy, External Components, Longman Group, UK, 1994.