THERMAL INSULATION METHODS FOR

HOUSING WITH REINFORCED CONCRETE STRUCTURE

Murat Aygün, Ph.D,

Hülya Kuş, Ph.D.

Division of Building Construction, Department of

Architecture

INTRODUCTION

Inadequate

or deficient application of thermal insulation gives rise to substantial

failures. Primarily, as a consequence of

excessive heat losses, energy is wasted and heating costs are increased

together with environmental pollution.

Almost all new-built housing in Turkey, whether low or high rise, is

constructed with an in-situ reinforced concrete structural frame and external

walls of lightweight masonry, either aerated concrete or fired clay hollow

blocks.

This

study is concerned with the effective use of thermal insulation in the category

of buildings described above, from the viewpoint of cold bridge avoidance. Alternatives of functional building elements

encountered most frequently in

The

constructional alternatives are subsequently compared in terms of performance

criteria such as condensation risk, heat storage capacity, and water

penetration. The position of thermal insulation and its relationships with

other components is explored in different floor, wall and roof configurations.

FUNCTIONAL ELEMENTS

The

alternatives of functional construction elements within the scope of this paper

are compared below in terms of performance criteria such as cold bridging, risk

of condensation, heat storage capacity and water penetration. Finally appropriate solutions are suggested

for each climatic region, based on both theoretical and experiential

knowledge.

1. Basements

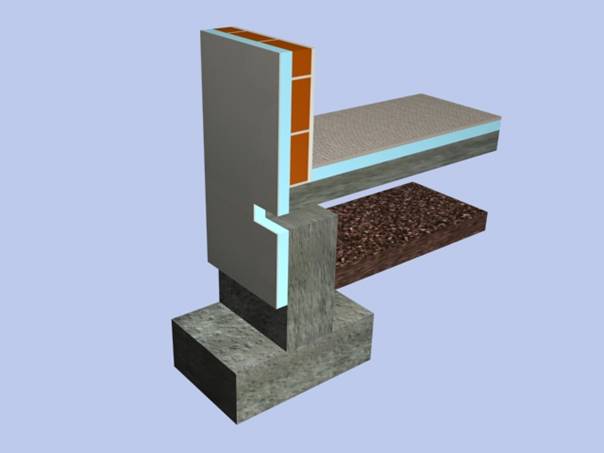

1.1. Basements with

External Tanking

1.1.1. Basement without Insulation

Basements

can be conceived in a variety of ways. They

may cover whole of the plan area of a building or only a part of it. Depending on the slope and the levels between

the natural and filled ground some parts of the basement walls remain below and

some above the ground level. Also

depending on the type of use, the basement may be heated or not. These conditions have to be born in mind when

deciding on the method of insulation of basements.

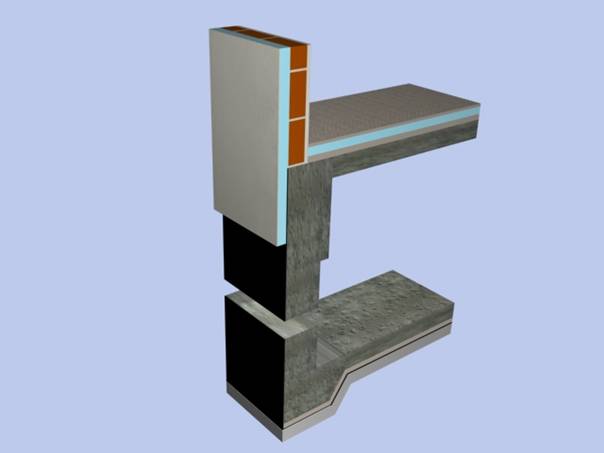

1.1.2. Unheated Basements

In

this case the most effective position for the horizontal insulation is above

the ground floor slab where the latter can adjoin the external envelope, hence

be continuous and also allows floor heating.

Heat flow into the basement is therefore reduced along the

perimeter. The insulation material must

have adequate compressive strength to resist point loads. A less satisfactory position in terms of cold

bridging is below the ground floor slab.

If there is to be external insulation on the wall, then this must extend

below the ground frost level.

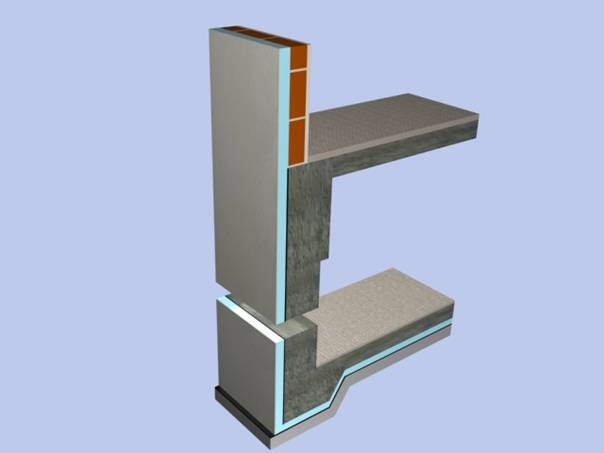

1.1.3. Heated Basements

In

the case of the basement required to be heated, the walls must be insulated,

preferably on the outside continuing up above ground level. The insulation material needs to be water-resistant

and sufficiently rigid to withstand lateral water and soil pressure. Additionally, insulation is also required to

be laid over the basement floor slab, especially in cold regions.

2. Floors

2.1. Ground Floors Resting on Soil

2.1.1.Uninsulated Floors

Heat

flow per unit area through floors to the ground is less than that through walls

to external air due to the heat storage capacity of ground. In mild climates there is no necessity for

complete floor insulation, which is omitted in practice anyway.

2.1.2. Floors with Perimeter Insulation

In

mild climates where the ground temperature does not fall too much, insulating

only either the outside or inside of edge beam may be adequate because of the

high heat storage capacity of soil. In

the outside position continuity of insulation over the exterior is achieved,

provided that the detail is compatible with that of above-ground wall

insulation. In the inside position there

are no detailing difficulties to overcome at the expense of discontinuity of

insulation.

2.1.3. Completely Insulated Floors

In

cold regions insulation should best be laid below the oversite slab to benefit

from its heat storage capacity. However,

if insulation is to be above, as in the case of floor heating then a vapour

barrier is required against condensation on the warm side of insulation.

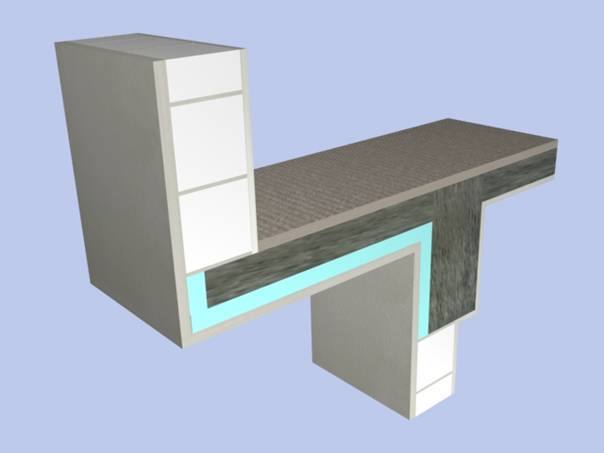

2.2. Raised Ground Floors

2.2.1. Uninsulated Floors

Floors

may be raised above ground level for various reasons, such as topography,

architectural design or use of prefabricated components. In this case an air space is formed below the

slab and needs to be ventilated adequately through holes in the edge beam. Because of this requirement for ventilation

significant heat losses occur through the uninsulated floor.

2.2.2. Insulated Floors

Insulation

is most effectively placed over the floor slab to eliminate cold bridges, also

enabling floor heating to be installed.

If it lies below the slab then application difficulties are encountered

as well as heat losses through the perimeter.

2.2.3. Insulated Floors and Walls

The

same detail as above applies here, where the walls are externally

insulated.

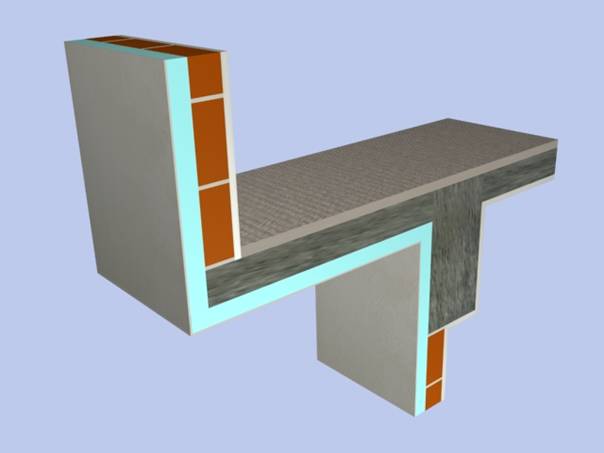

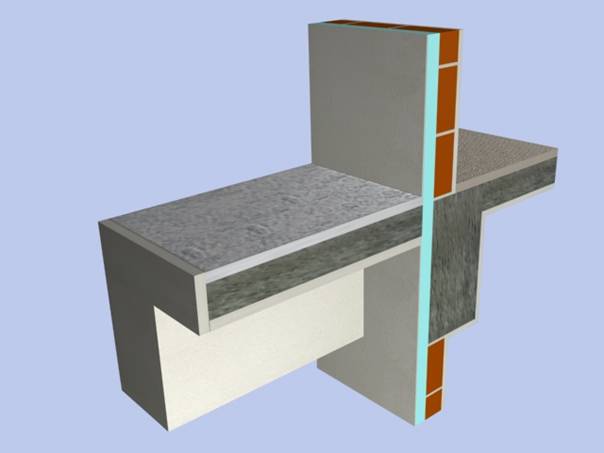

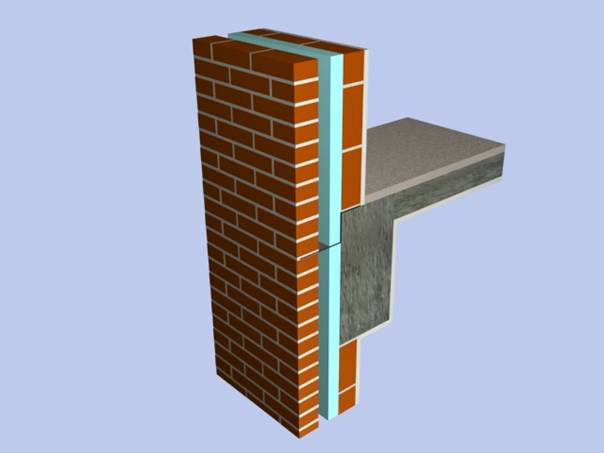

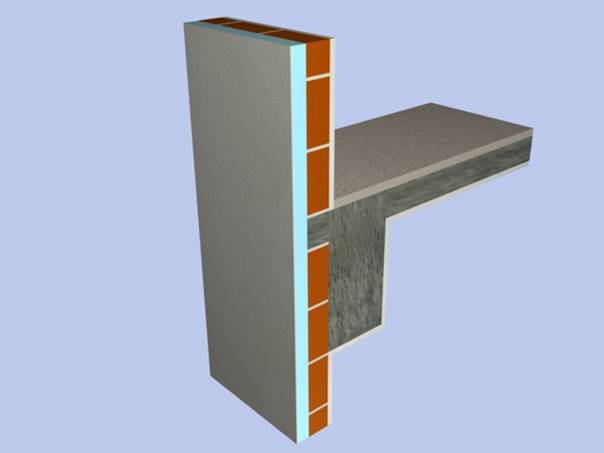

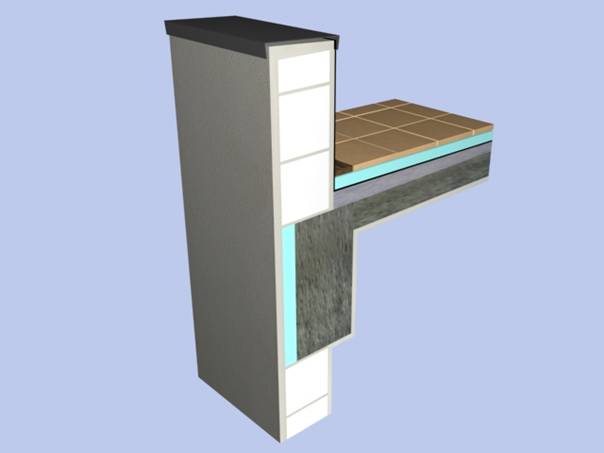

2.3. Cantilevered Upper Floors

2.3.1. Uninsulated Floors

The

upper floor slab may be projected outwards along all or part of the elevation

in order to increase the enclosed floor area.

The upper and lower external wall planes are thereby seperated. Since now a horizontal discontinuity of

insulation is inserted between the two wall planes, a cold bridge is

created.

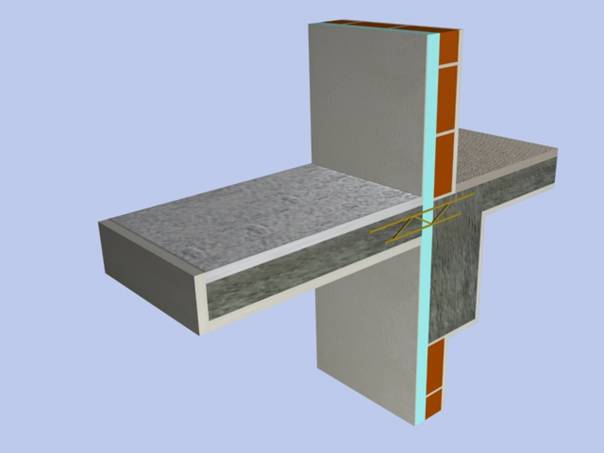

2.3.2. Floors with Insulated Soffit and Sides

Insulation

may be applied to the soffit and sides of cantilever to eliminate cold

bridging. External wall blocks can then

be laid so that they project by a certain amount beyond the slab edge to allow

insulating material to be positioned on the slab soffit and sides as well as on

the column external face. The thermal

resistance at these points can be similar to that of the wall. Expanded metal lath or equivalent material is

required over the joint between masonry and insulation to prevent cracks on the

external rendering.

2.3.3. Floors with Complete External

Insulation

Insulation

is most effectively used when it is continuous over the walls (detailed in

3.1.3) as well as the cantilever soffit and sides. The soffit construction should be capable of

allowing internal moisture to escape by evaporation.

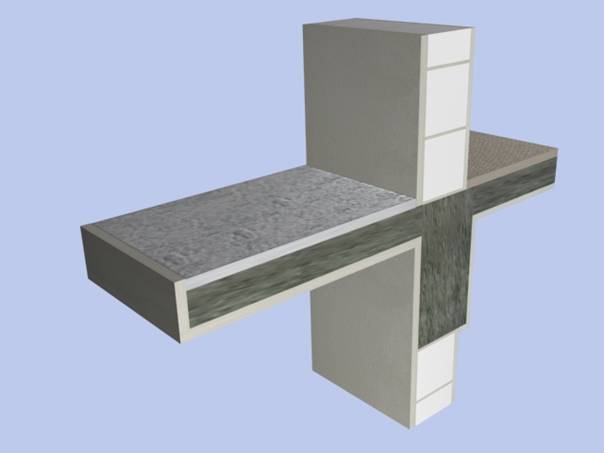

2.4. Balconies

2.4.1. Uninsulated Balconies

Significant

heat losses occur through balcony slabs.

They also present critical constructional problems in eliminating cold

bridges. Especially insufficiently

insolated balconies remain wet over long periods and give rise to greater heat

losses together with possible condensation.

2.4.2. Simply Supported Balconies

Instead

of projecting the floor slab beyond the external wall, only the floor beams

perpendicular to the wall can be extended outwards supporting an in-situ or

precast one way span balcony slab. Hence

the area of cold-bridging is restricted only to the sectional area of the

projecting beams and the heat loss is reduced compared to that through a

cantilevered canopy.

2.4.3. Balconies with Specially Reinforced

Slabs

In

order to eliminate the cold bridge between the balcony and floor slabs, the

former can be cantilevered by special high-tensile steel reinforcement and the

gap inbetween filled with insulation.

This solution involves special care but enables the continuity of insulation

on the external wall.

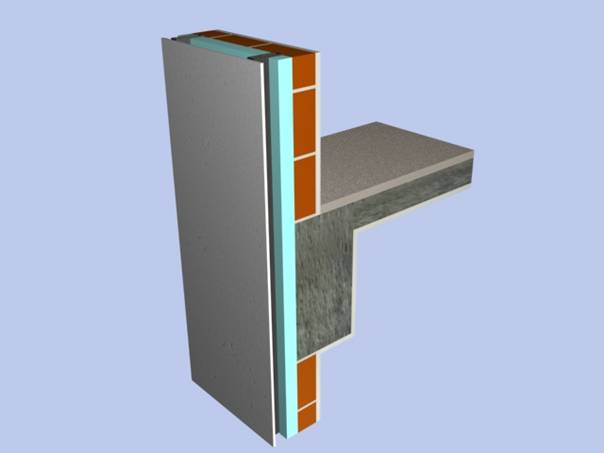

3. External Walls

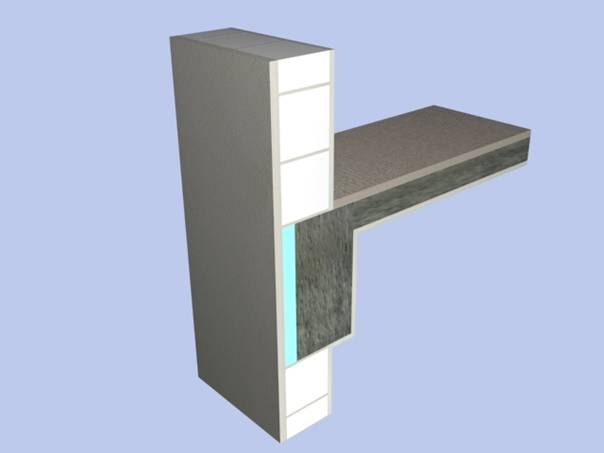

3.1. Infill Walls Between Columns

3.1.1. Unventilated Walls

3.1.1.1 Uninsulated Walls

In

reinforced concrete frame buildings, walls are mostly constructed on the edge

of the floor slab and between columns.

The wall material is chosen as either lightweight concrete or hollow

fired clay blocks. Then a rendering is

applied to the outside and a plastering inside.

Even though the wall thickness may provide sufficient thermal

resistance, the adjacent columns on either side and the floor slab at the top

and bottom surrounding the wall remain as cold bridges without any

supplementary measures.

3.1.1.2 Walls with Insulated Columns and Beams

If

no additional insulating material is intended to be used on the walls then the wall

thickness may have to be increased nuch more than required for stability. However the surrounding column and slab faces

still require to be insulated with a suitable material. The joint between insulation and wall needs

to be covered with an expanded metal lath or similar material so that cracks

are avoided on the rendering over this joint between two dissimilar

materials. In order to obtain a flat

facade the wall must project beyond the edge of slab by a small amount

(30-50mm) to accommodate the thickness of insulation material. On slender walls (<150mm) the adverse

effect of this projection on stability has to be considered and possibly the

thickness increased.

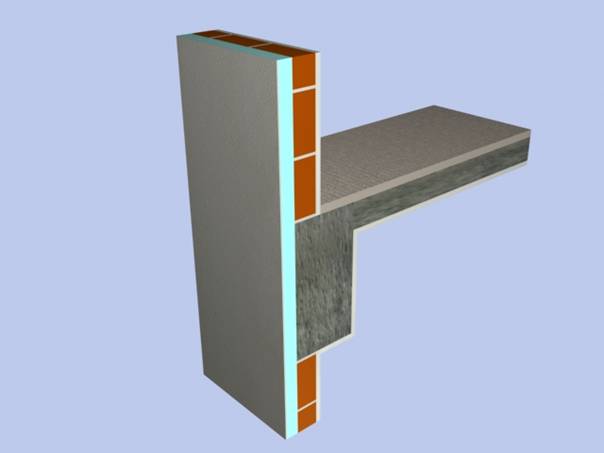

3.1.1.3 Walls with Complete External Insulation

This

method of wall insulation eliminates cold bridges effectively. Wall thickness is determined only with

respect to stability and is therefore reduced.

The heat storage capacity of wall material contributes to the thermal

performance of the wall and hence to the internal climate, decreasing the

energy consumption. The weight of wall

is less and the usable floor area more compared to a single layer wall. On the other hand this method involves

special details around openings, different trades and closer site

supervision.

3.1.2. Insulated and Ventilated Walls

3.1.2.1 Cavity

Wall with Masonry Outer Leaf

In

humid regions, where rain penetration and condensation are more likely to

occur, this type of wall construction is suitable, especially on the north and

east facades. The outer leaf acts as a

weather shield. Gaps at the top and

bottom allow the cavity to be ventilated and drained, removing any moisture on

the insulation. Heat storage capacity of

the inner leaf also improves the thermal performance of the wall. However this multi-layer construction

necessitates some accessories such as cavity ties, support angles, cavity trays

and requires high quality of workmanship.

3.1.2.2 Cavity

Wall with Lightweight Cladding

This

type displays a similar physical performance to that of 3.1.4.1. A light-weight carrier frame is fixed to the

masonry behind. Subsequently insulation

is inserted between the frame members to which external cladding is fixed. An air cavity is left between insulation and

cladding. Compared to the wall with

masonry outer leaf described above, the weigttt is less and total thickness

smaller.

3.1.2.3 Cavity

Wall with Insulated Lightweight Cladding

In

hot regions the cladding may be insulated to prevent overheating of the wall. The air cavity provides cooling by convection

and wind. This type is particularly

effective on south and west facades.

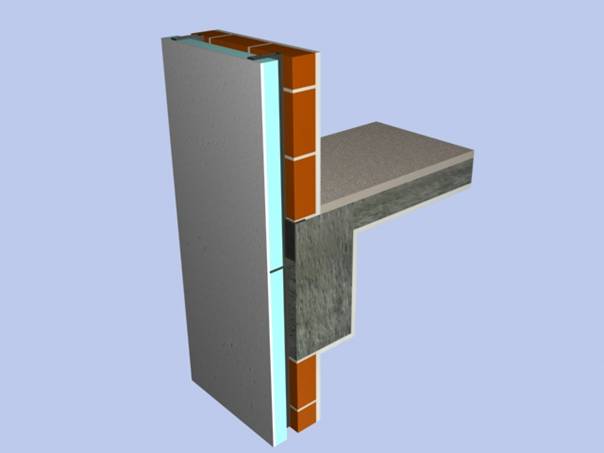

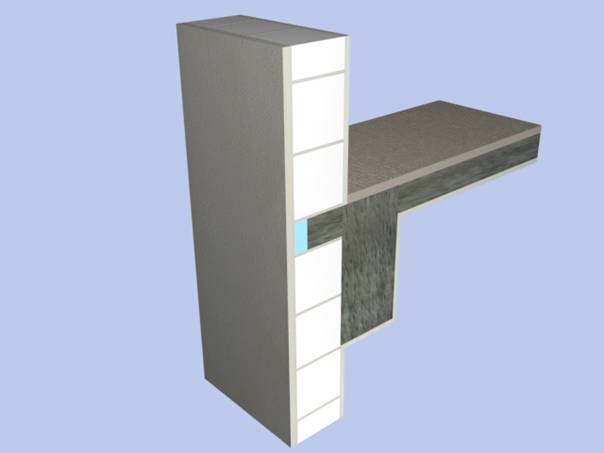

3.2. Infill Walls on the Outside of Columns

3.2.1. Uninsulated Walls

Cold

bridges along columns, as illustrated in 3.1.1., can be avoided if the floor

slab or a shallow edge beam is projected beyond the outer face of columns and

the external wall is supported by this cantilever. In such a situation only the face of the

floor slab or the edge beam creates a cold bridge. However rigidity of the wall construction Is

reduced because the walls are not restrained by columns. Therefore ties are

required to attach the walls to the columns.

Additionally, since walls are continuous in the horizontal direction,

vertical movement joints should be left at certain distances. Another drawback of this solution compared to

3.1.1. is that the external columns are not contained within the wall

thickness, resulting in some loss of usable floor area.

3.2.2. Walls with Insulated Outer Face of

Floor Slab

The

outer face of horizontal structural elements can be insulated to overcome

cold-bridging. In this case the wall is

brought forward of the slab edge by the same amount as insulation thickness.

3.2.3. Walls with Complete External

Insulation

This

detail is a superimposition of 3.1.3. and 3.2.2., each one of which, in actual

fact, is quite adequate on its own and can only be cost-effective in extremely

cold regions or where a very uniform surface temperature distribution is

required inside.

4. Roofs

4.1. Sloping Roofs

In

these roofs, if heat and sound insulation is placed on the sloping surface, the

area to be insulated is greater than that of the flat roof because of its geometric

properties.

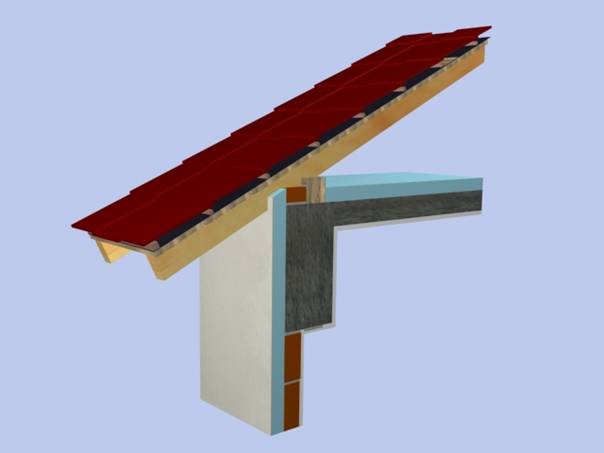

4.1.1 Roofs with

Rafters

4.1.1.1

Roofs with Thermal Insulation on Slab

In

this solution, also known as cold roof, the heat insulation is placed over

the roof slab and the attic space remains cold.

There should be ventilation provided along the eaves and ridge. As the slope decreases, an increase in the

ventilation opening is required. There

is an application ease in this option.

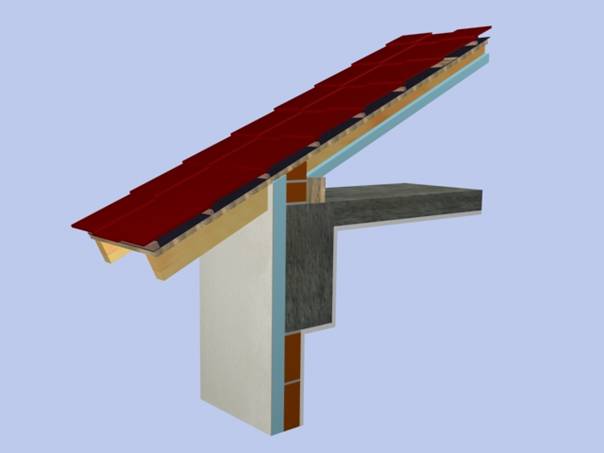

4.1.1.2 Roofs with Thermal

Insulation between or under Rafters

In

both cases ventilation is required in any gap between the rafters. If the insulation is placed between the

rafters, the thickness of the roof is decreased. The distance between the rafters should be

suitable for the insulation pannels dimensions to fill the openings

completely. There should be at least 5cm

gap between the rafters top edge and the insulation layer.

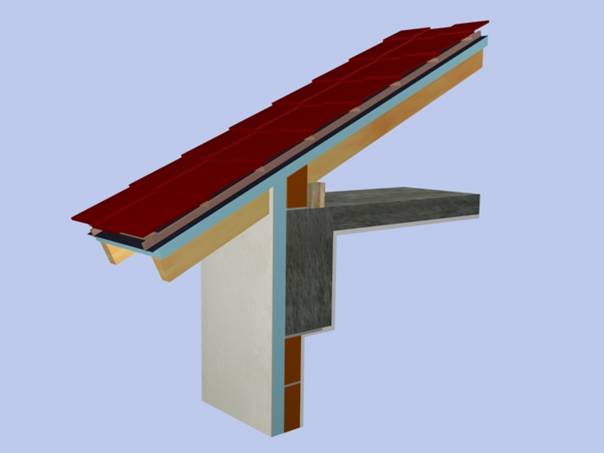

4.1.1.3 Roofs with Thermal

Insulation over Rafters

Thermal

insulation and waterproofing layer above are laid over rafters continuously. Gaps along battens would be helpful for

drainage of water leaking between tiles or additional counter-battens can be

used for drainage. In cases of a high

risk of condensation a vapour barrier is used on the inner surface of heat

insulation.

4.1.2. Roofs with

Slab

Rafters

are sustituted by a concrete slab to form the roof plane.

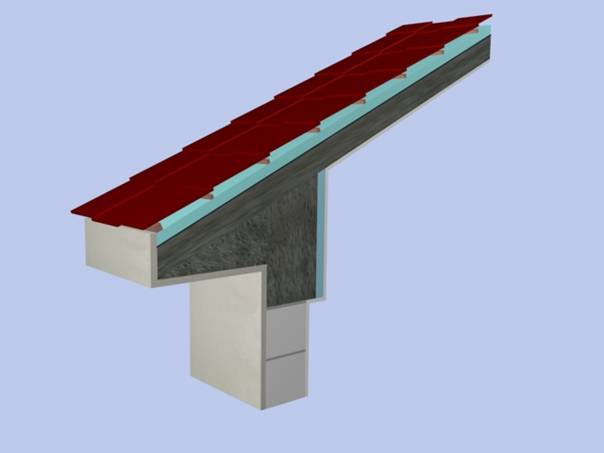

4.1.2.1

Roofs with External Thermal Insulation

4.1.2.1.1 Roofs without Ventilation

The

heat bridges could be blocked if the heat insulation over the sloped slab also

covers the eaves. A narrow eaves is more

rational in this option. The heat

storing capacitiy of the slab reduces the load of space heating. The application of the roof finish should be

carried out without damaging the waterproof layer or impermeable seals should

be used.

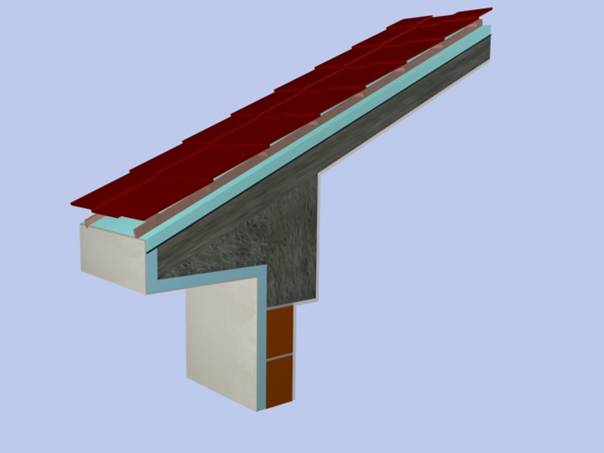

4.1.2.1.2 Roofs with Ventilation

By

evaluating the solution before, a ventilation layer can be composed by the help

of laths that is placed parallel to the slope.

The drainage of water that is leaked from the coating or the vapour

reached from the inner volume is procured with this ventilation layer. Building a narrow eaves or building it with

metal suffixes would be useful for the application.

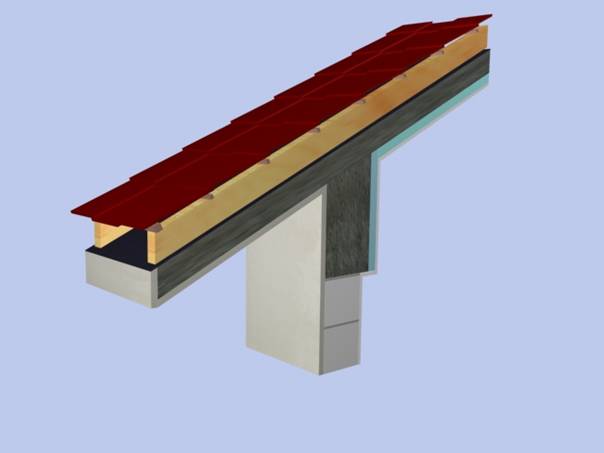

4.1.2.2 Roof with Internal Thermal Insulation

(Ventilated or Non-ventilated)

The

heat insulation could be placed on the inner surface of the roof slab for heating

the inner space in a shorter time and obviating the need to insulate around

wide eaves. Ventilation and water

drainage is achieved between the rafters on the slab, and roof finish placed

over those rafters. This application

calls for a finish and vapour barrier on the inner surface.

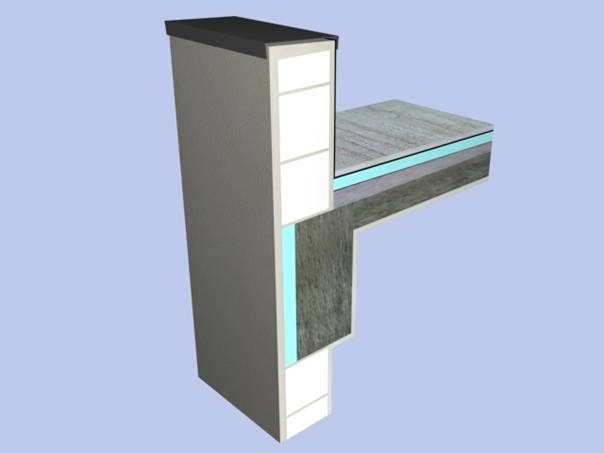

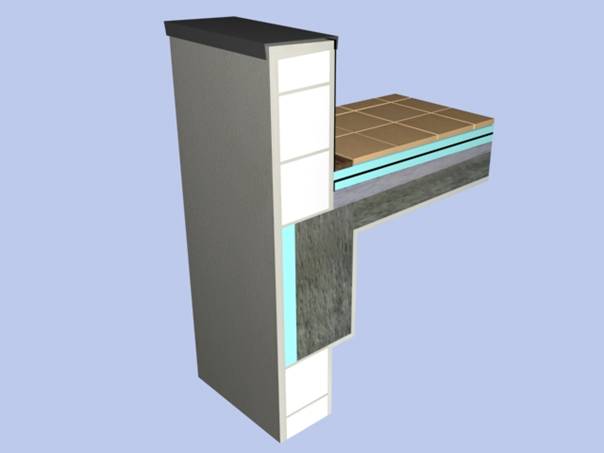

4.2 Flat Roofs

4.2.1

Warm Roofs (Ventilated or Non-ventilated)

In

the case of using an open cellular heat insulation material, this should be

covered by a waterproofing membrane resistant to sunlight effects, with a

vapour barrier underneath. The vapour

barrier may not be needed if ventilation is possible over the heat

insulation. A sufficient thickness of the parapet can prevent heat

bridging in this option.

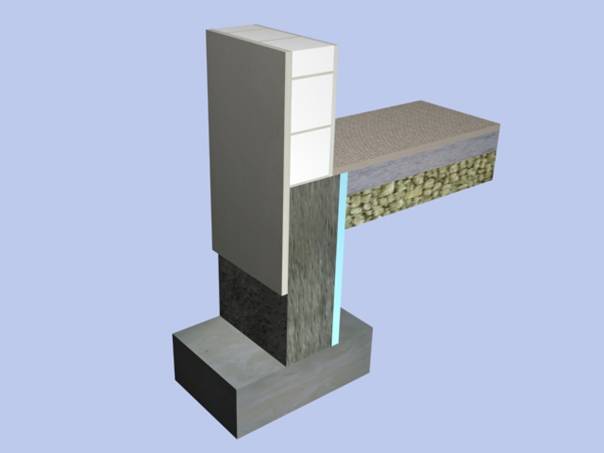

4.2.2 Inverted Roofs

Closed-cell

extruded polystrenes makes placement of the heat insulation over the

waterproofing membrane possible which is thus protected during the construction

period and allows foot traffic over the roof.

Moisture condensation is prevented without using a vapour barrier. Heat insulation panels should be thicker than

those for sloping roofs as the latter are allowed to get wet.

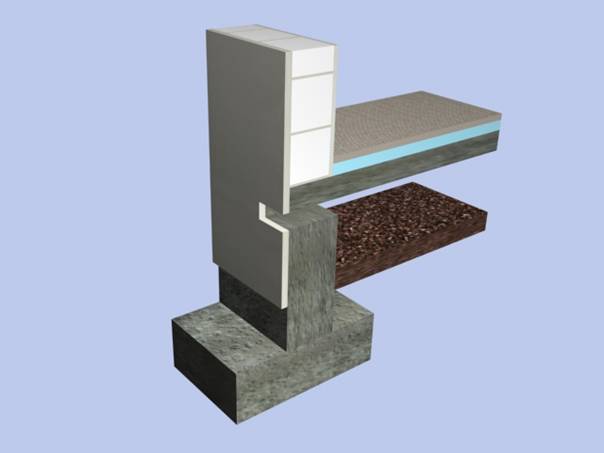

4.2.3 Advanced Inverted Roofs

By

developing the previous solution further, the total thickness of the heat

insulation can be smaller. This option may be more viable for

applications over the existing waterproofing layer.

Reference